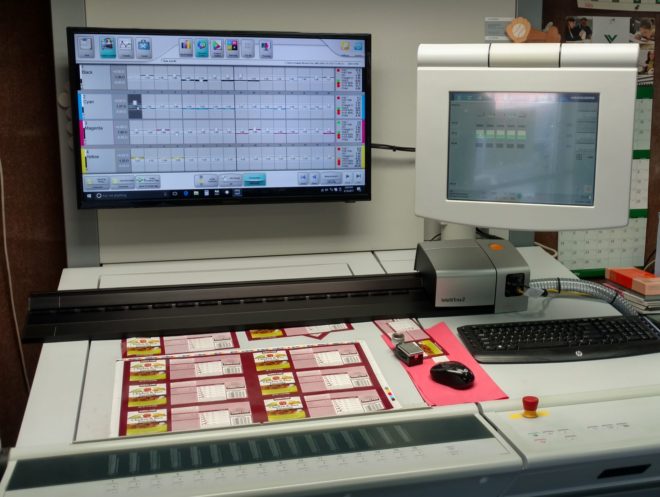

Exact 2

The new Exact 2 is the replacement for the very successful Exact spectrophotometer.

It has a revolutionary camera based aperture system, improved accuracy and inbuilt pantone libraries.

It supports Colorcert, Color IQC and Presssign software and can now connect by WIFI

The larger screen offers improved visual perception of Colourspaces and the unit can be calibrated using Net Profiler software.

CXF data transfer is seamless using the Exact Manager suite software and all units are scan enabled to automatically measure a colour bar.

There are templates for all ISO standards including Fogra 39,47,51 and 52 giving pass fail information immediately on measurement.

Full onsite training is always offered to gain the most out of this device.